Professional 3D Printing Course

3D Printing certified course that offers substantial training to use 3D printing technology from basic to advanced.

7 Weeks

Practical Learning

Expert trainers

DESIGNED WITH EXPERTISE

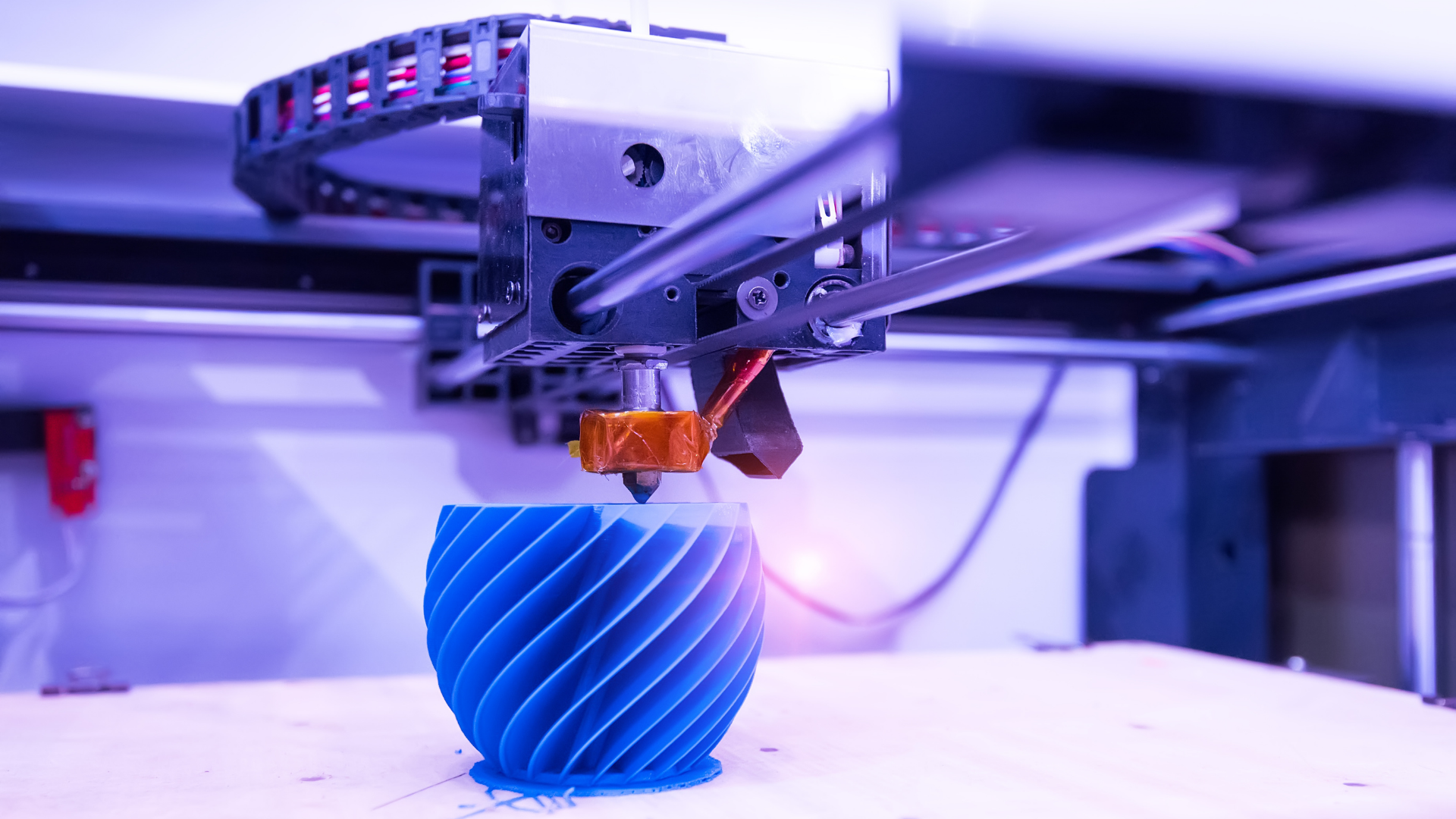

What is 3D printing or Additive Manufacturing?

In the 21st century global economy, the knowledge and understanding of 3D printing stands beneficial for students. This technology makes it possible to run manufacturing businesses on near autopilot mode.

The world of manufacturing has transformed.

3D printing or additive manufacturing service reduces the time and effort of the manufacturer to create a prototype. With the use of 3D printing tech more emphasis can be done on the research and design of a product. The manufacturers can invest their time in making a flawless product as the production cycle time is reduced. Computer Aided Design (CAD) softwares like Rhino, Tinker CAD, SolidWorks, Fusion 360 among others areused to create three dimensional designs digitally which are transformed into 3D physical models. This technology is used by manufacturing companies to create 3D models of airplane parts, prosthetic limbs, jewelry and even 3D-printed medications. 3D printing sparks greater creativity and collaboration in solving problems.

Why should you enroll for this 3D printing course?

- 3D Printing has the potential to be in every houseful used by students and professionals from all walks of life

- From beginners to experts. No prerequisites.

- Practical learning that’ll help you in the real world

- Preparing for various 3D printing industries and its application

- Systematic assignment for understanding core concepts

- Self-paced learning

- Live practical sessions

- Recorded sessions for revision during the course

- Lifetime access to course upgrades

- Articles/blogs and Manual

- Quiz

- Economic pricing policies

WHY JOIN LEARNATHON

Focus on practical learning

Live Projects

1-on-1 Mentorship

Blended Learning

E-book + Articles

Industry/Market visits

Who can be a part of this course?

Students

Tech Lovers

Professionals

Jewelry

Designer

Architects

Architects

Managers

Doctors/

Dentists

Engineers

Product

Designers

Hobbyists

Teachers

Learners

Business of Gifting/

Corporate Gifting

Fashion

businesses

Anyone who wishes to upgrade, upskill or start a new venture

Curriculum

MODULE 1:

Introduction to 3D printing

- Understanding the term Rapid prototyping and Additive Manufacturing (AM)

- Difference between conventional and AM with the help of videos

- Difference between CNC and AM with the help of videos

- Evolution of 3D printing

-

Principles of 3D printing

- Generic AM process - conversion of design ideas into iteration

- STL concept

- General integration of an AM machine

- Materials used for printing like thermoplastics, resins, biomaterials and metal + Applications of the same in different industries

- Technical skills involved in 3D printing

- Need & Benefits of 3D printing

- Growth in industries using 3D printing

- Practical Assignments

MODULE 2:

Types of 3D printing processes

- Classification of AM processes

-

Explanation of each process with videos

- Features of 3D printed parts - explanation with images

- Design for AM

- Practical Assignments

MODULE 3:

TinkerCAD

- Design of assemblyConversion of 2D to 3D

- About Tinkercad & its use for beginners

- Tools & commands using Tinkercad

- Converting ideas in 2D

- Process of drafting 2D environment, 2D geometrical creation and 2D designing

- Concepts of CAD

- Topology Optimization with case studies

- Practical Assignment

MODULE: 4

Fusion 360/ Sketch up

- Introduction to Fusion 360 and its benefits in 3D design

- Transition from Tinker cad to Fusion 360

- Learning powerful tools to represent our ideas into reality

- Interface checking and transition from 2d environment to 3d environment

- To build basic 3d shapes and sketched based shapes

- Practical Assignment

MODULE 5:

3D Printers & Scanners

- Types of FDM printer

- Components of a FDM 3D printer

- Introduction to G code

- Demonstration of 3D printer

- Calibrating 3D printing

- Types of 3D scanners

- Practical Assignment

MODULE 6:

Slicing and Slicing software

- Conversion of 3D design to printable version

- Slicing and tessellation

- Slicing software Cura/ Chitubox

- Important variables for an optimized print

- Knowledge on bases, supports and overhangs

- Optimizing surface finish and cost

- Practical Assignment

MODULE 7:

Materials for 3D printing

- Material used for various 3D printers

- Meshmixer basic skills

- Software Commands

-

Practical Assignment

MODULE: 8

Applications of 3D Printing

- Existing application sectors with case studies/videos like Jewelry, Bio-Medical and many other industry

- Direct Digital Manufacturing (DDM)

- Manufacturing vs prototyping

- Practical Assignment

MODULE: 9

Post Processing

- Post Processing operations after 3D printing

- Casting techniques

- CNC & laser cutting techniques

- Die making and liquid mould

- Practical Assignment

MODULE: 10

Other aspects of 3D Printing

- Impact of low-cost AM system

-

Intellectual property

- 3D manufacturing regulations and carbon footprint

- Practical Assignment

MODULE: 11

Business opportunities

- Ideas for startups with 3D printing

- Product design and development using in house 3D printers

MODULE: 12

Future of 3D printing

- Futuristic applications like construction, food printing etc. with case studies

- How 3D printing has supplemented/ replaced conventional manufacturing using industry examples

- Reverse Engineering using case studies.

MODULE: 13

Other

aspects of 3D Printing

- Quiz

- Project submission/ Examination

- Certificate of

Professional Course on “3D printing technology”

Let's get started!

Professional 3D Printing Course

Write your awesome label here.